Mitech MDW-TW 10000 Micro-Control Series Gantry La

Mitech

Maximum testing force (N) 10000N

Better than ±1%(±0.5%)

Approximately 450kg

700*580*1720mm

Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

Product OverviewMitech MDW-TW micro-control series gantry landing type spring tension and compression testing machine,by microcomputer control motor drive screw motion, for a wide variety of spring tension and compression experiment was carried out, it adopts the built-in controller, AC servo motor, stable performance, strong structure, high reliability, simple operation and high degree of automation. Computer-aided means to achieve powerful functionality. Widely used in spring manufacturing, low-voltage electrical appliances, power machinery, institutions of higher learning and scientific research units and other fields.It is the necessary professional precision testing equipment for improving production efficiency and saving production costs.

Function & application

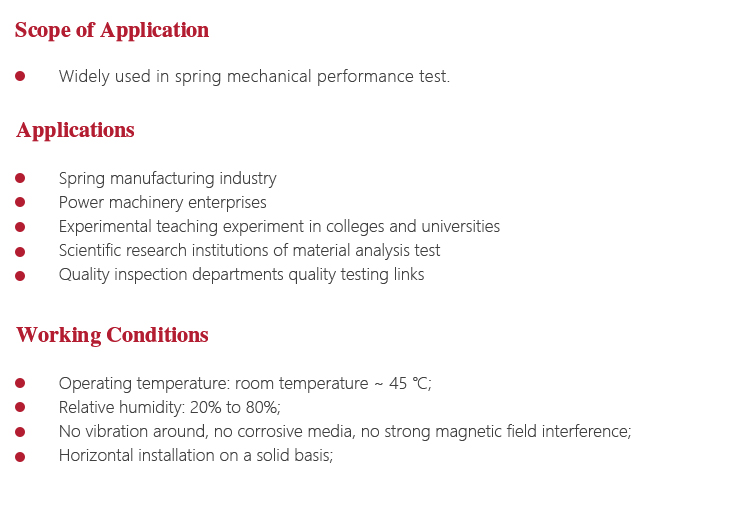

Function & applicationWidely used in spring mechanical performance test.

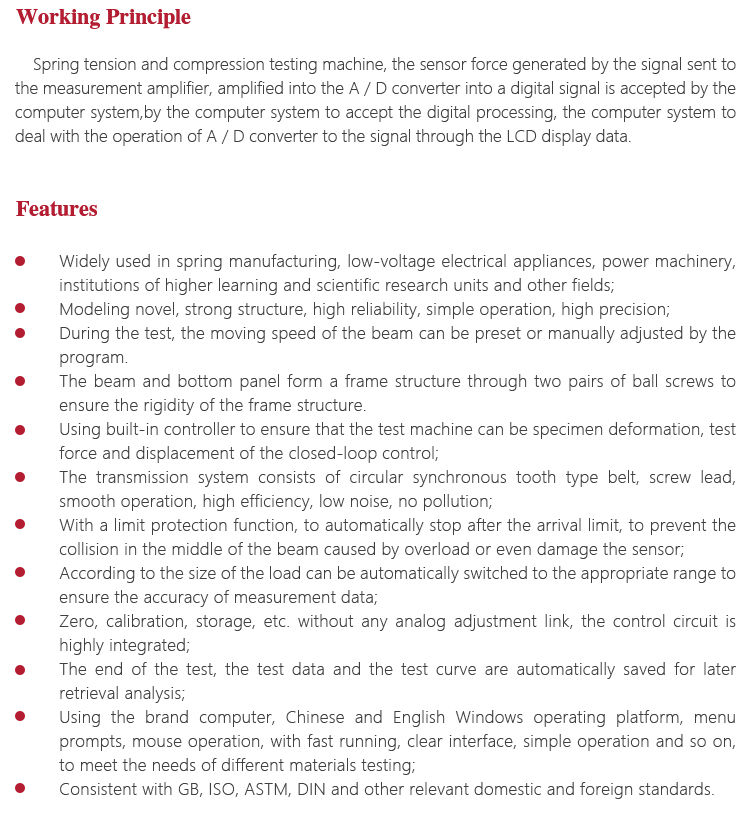

Working Principle

Working PrincipleSpring tension and compression testing machine, the sensor force generated by the signal sent to the measurement amplifier, amplified into the A / D converter into a digital signal is accepted by the computer system,by the computer system to accept the digital processing, the computer system to deal with the operation of A / D converter to the signal through the LCD display data.

Working Conditions

Working Conditionsl Operating temperature: room temperature ~ 45 ℃;

l Relative humidity: 20% to 80%;

l No vibration around, no corrosive media, no strong magnetic field interference;

l Horizontal installation on a solid basis;

Instrument Features

Instrument Featuresl Widely used in spring manufacturing, low-voltage electrical appliances, power machinery, institutions of higher learning and

scientific research units and other fields;

l Modeling novel, strong structure, high reliability, simple operation, high precision;

l During the test, the moving speed of the beam can be preset or manually adjusted by the program.

l The beam and bottom panel form a frame structure through two pairs of ball screws to ensure the rigidity of the frame

structure.

l Using built-in controller to ensure that the test machine can be specimen deformation, test force and displacement of the

closed-loop control;

l The transmission system consists of circular synchronous tooth type belt, screw lead, smooth operation, high efficiency, low

noise, no pollution;

l With a limit protection function, to automatically stop after the arrival limit, to prevent the collision in the middle of the beam

caused by overload or even damage the sensor;

l According to the size of the load can be automatically switched to the appropriate range to ensure the accuracy of

measurement data;

l Zero, calibration, storage, etc. without any analog adjustment link, the control circuit is highly integrated;

l The end of the test, the test data and the test curve are automatically saved for later retrieval analysis;

l Using the brand computer, Chinese and English Windows operating platform, menu prompts, mouse operation, with fast

running, clear interface, simple operation and so on, to meet the needs of different materials testing;

l Consistent with GB, ISO, ASTM, DIN and other relevant domestic and foreign standards.

Operating Method and Attentions

Operating Method and Attentions Instrument Maintenance

Instrument Maintenancel Before using this instrument, please read the instruction manual carefully, understand the operation steps and precautions,

avoid the damage caused by improper operation or personal safety accident;

l Test machine is a large precision instruments, should pay attention to water, moisture. Exposed workstations, upper and

lower beam parts and attached parts should be coated with anti-rust oil to prevent rust;

l If idle for a long time, at least once a week and move the upper and lower beams, so that beam position, silk mother often

activities to prevent rust;

l Should be at least once a year for the instrument to do periodic testing to ensure the accuracy of the test machine;

l Electrical connection cable and equipment should be careful when connected, moderate efforts, remember not to swipe,

hard pull.

l Don’t disassemble the instrument without authorization, maintenance related matter, please contact MITECH after-sale

service department with 4000600280.

-

-

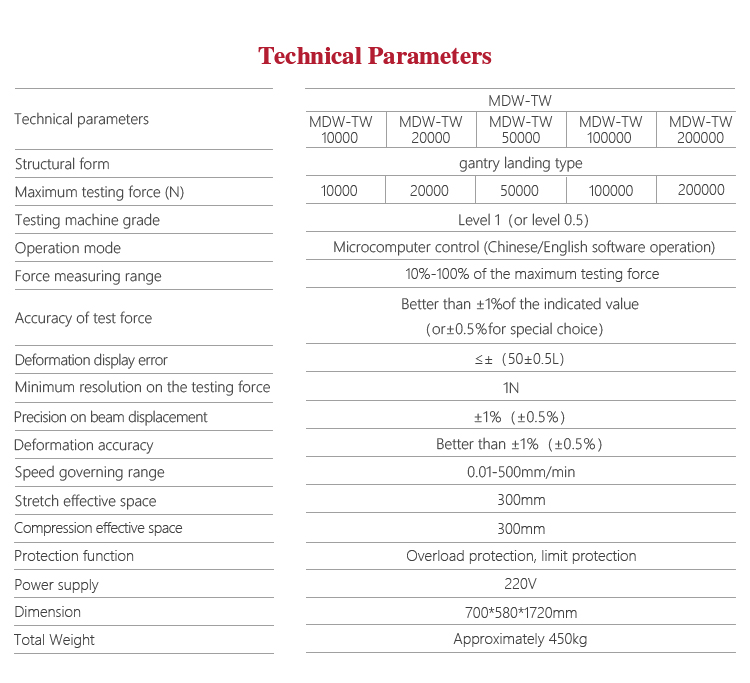

Structural form gantry landing type Maximum testing force (N) 10000N Testing machine grade Level 1 (Level 0.5) Operation mode Microcomputer control (Chinese and English software operation) Force measuring range 10% -100% of the maximum test force Accuracy of test force Better than ± 1% of the indicated value (or ± 0.5% special Deformation display error ≤±(50±0.5L) Minimum resolution of test force 1N Beam displacement accuracy ±1%(±0.5%) Deformation accuracy Better than ±1%(±0.5%) Speed range 0.01-500mm/min Stretch test the maximum distance between two hooks 650mm Compression test the maximum distance between two platens 650mm Protection function Overload protection, limit protection. Power supply 220V Dimensions 700*580*1720mm Total weight Approximately 450kg -

-