Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

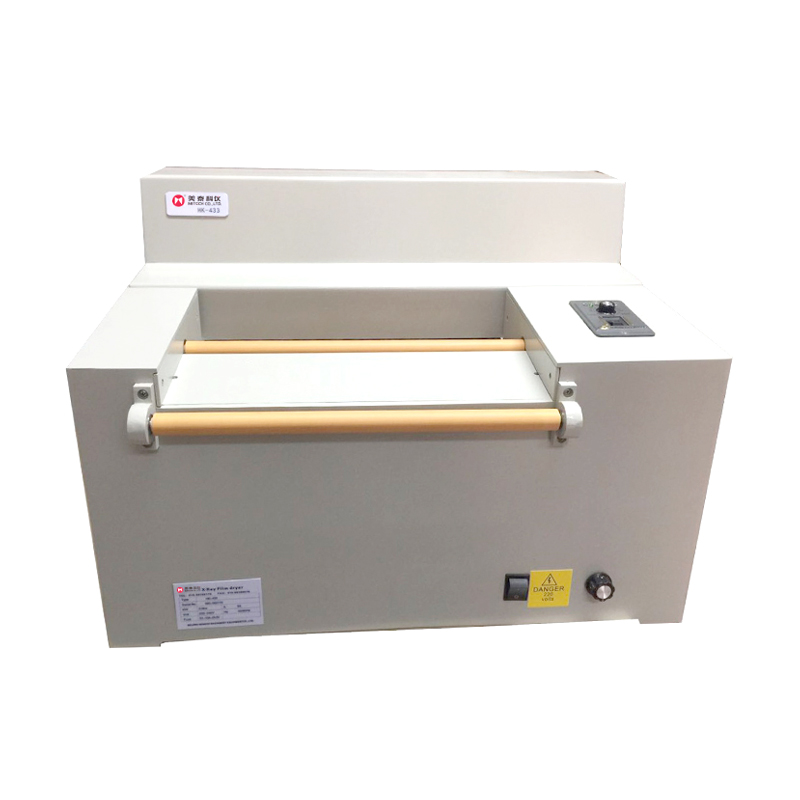

Product OverviewMITECH Film auto-dry machine MD-500 is mainly used to quickly dry the film after ray detection. It adopts PU roller and soft rubber roller to convey film. Together with good water absorption sponge shaft, it can quickly and efficiently dry the film without water and damage. Multi-functional as it is, the spinning speed is adjustable and thus makes it convenient to operate.The film can be washed again by external water source or inner water sink. The circulation pump makes it possible to supply clean water when necessary. In a word, MD-500 is the necessary equipment for ray detection.

Function & application

Function & applicationMITECH Film auto-dry machine MD-500 series products is mainly used in drying process of Manually washed X-ray film, such as photography, medical, scientific research, industrial and other fields.

Working Principle

Working Principle Working Conditions

Working Conditions Instrument Features

Instrument FeaturesEasy operation, fast speed, high efficiency;

Muti-functional design, Two - way water source;

Operation without water marks or damage;

Inner circulation pump to supply clean water automatically;

Operating Method and Attentions

Operating Method and AttentionsOperation

Use anhydrous cycle

Fill the water tank with clean water, and switch the water inlet into the no-load position;

Open the drain valve to drain until there is no blisters; put the water pipe into the bottom of the bucket, and set the switch in the position of two. If there is water out on the surface of the water tank, you can adjust the drain valve to control the flow of water, regulating valve range is generally within 45 °. After the adjustment, check whether the water continues to emerge. The purpose of this operation is to achieve the cycle of water up and down;

When everything is normal, put into the roller group, cover the cover, then you can use it.

External water source

External water source, open the water switch, put the change-over switch in the position of one ,then you can use it.

Instrument Maintenance

Instrument MaintenanceBefore working, make sure to clean the platform and body to avoid dust and dirt;

Check if the peripheral equipment is connected normal. Liquid level should be upper 1/3 of the bucket. The tube should be at the bottom and do adjust the overflow pipes at suitable position;

Open the cover, wipe out the water drops as liquid vapor. Check is there is crystallization or dirt on the surface of drive roller. Fill water into the cleaning tank after wiping out;

Press the annual supply water button, check if it works properly;

It can run only when the machine is heated at the setting temperature;

Before working, putting into a piece of old clean film to make sure the machine works well;

After work, shut down the power and water inlet, draining is also needed. Open the cover a little bit to avoid condensation. Keep ventilated if possible.

-

-

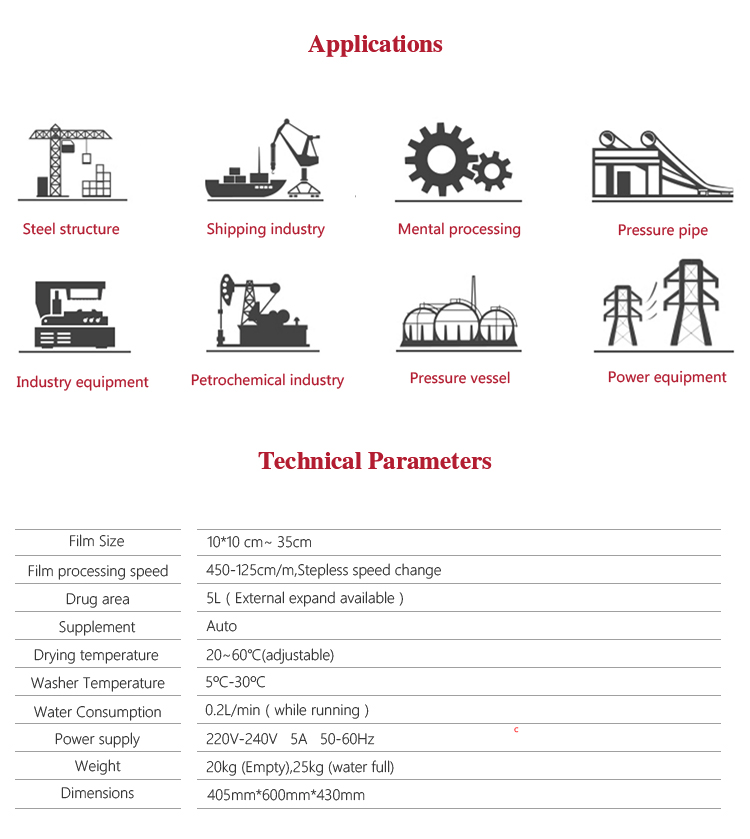

Film size 10*10 cm~ 35cm Film processing speed 450 - 125 cm/m, Stepless speed change Drug area 5.0 L (External expand available) Supplement Auto Drying temperature 20-60 ℃ (adjustable) Water temperature 5℃-30℃ Water Consumption 0.2 L/m (while running) Power supply 220-240V 5A 50-60Hz Weight 20KG (empty) 25KG (water full) Dimensions 405mm*600mm*430mm -

-